Students explore engineering tech with new robotic arms

December 6, 2020

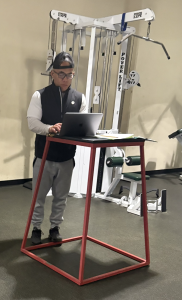

The engineering technology teacher at Palo Alto High School is improving the prospects of online learning in his classes by introducing programmable robotic arms into the curricula.

Last month, each student in the 10-person engineering technology class received robotic arm kits to construct their own mechanical masterpieces as a part of a new curriculum, according to Paly Engineering Tech teacher Christopher Kuszmaul.

Every Tuesday, an employee from Evodyne, a Mountain View-based robotics company, joins the class and guides students through the construction of the robotic arm. Students use 3D-printed parts and an Arduino kit to assemble their arm.

“The process of constructing a robot arm, it gives you a lot of mechanical engineering exposure,” Kuszmaul said. “I mean, there’s the very fundamental things of what different kinds of machines there are, from the levers to wheel and axle.”

Kuszmaul said he has been looking for ways to improve his engineering students’ learning experience even before the COVID-19 pandemic.

“When COVID happened, I was looking more desperately for ways to put something physical in the hands of students that was related to robots,” Kuszmaul said.

He later partnered with Evodyne to supply the kits. The district paid $3,000-$3,300 for the kits at $300 each, with funding coming from the Carl D. Perkins Grant, a grant that provides supplemental funding available for CTE classes, Kuszmaul said.

According to Kuszmaul, the partnership has been mutually beneficial, supporting both the small company, by giving it customers, and the Paly students, by giving them new interactive learning material.

“Evodyne had shifted their business strategy, I think more towards something [educating students] which I needed,” Kuszmaul said. “So both of us were kind of running in parallel to each other at least metaphorically, but then when COVID happened, that kind of drove us together.”

Engineering tech students have been working on their robot arm for a month-long unit, and will soon pass it on to other students in Kuszmaul’s computer-aided design and computer science classes, he said.

Kuszmaul said he hopes that the robotic arm kits prove to be a useful learning resource for all his students — not just his engineering tech students — by extending the robot arm curriculum into the computer-aided design class and the computer science classes as well.

“The discussion I’m having with Evodyne, as well as a strategy for the general community, is how can we and how should we scale this because my vision is to have robot arm kits for virtually all my students,” Kuszmaul said.

Although Kuzmaul plans to eventually expand the robot arm curriculum to all of the classes he teaches, for now, he plans to purchase additional kits after the holidays so that there are 20-30 kits in use next semester.

“By May we could have had as many as 70 students do two units on the arm,” Kuszmaul said.